Padeye Designer / Inspector

An App to design a steel padeye by calculating critical stresses at designated sections in combination with standard shackle sizes.

It has four main pages:

- Data Centre

- Work Sheet

- Drafting Board

- Design Report

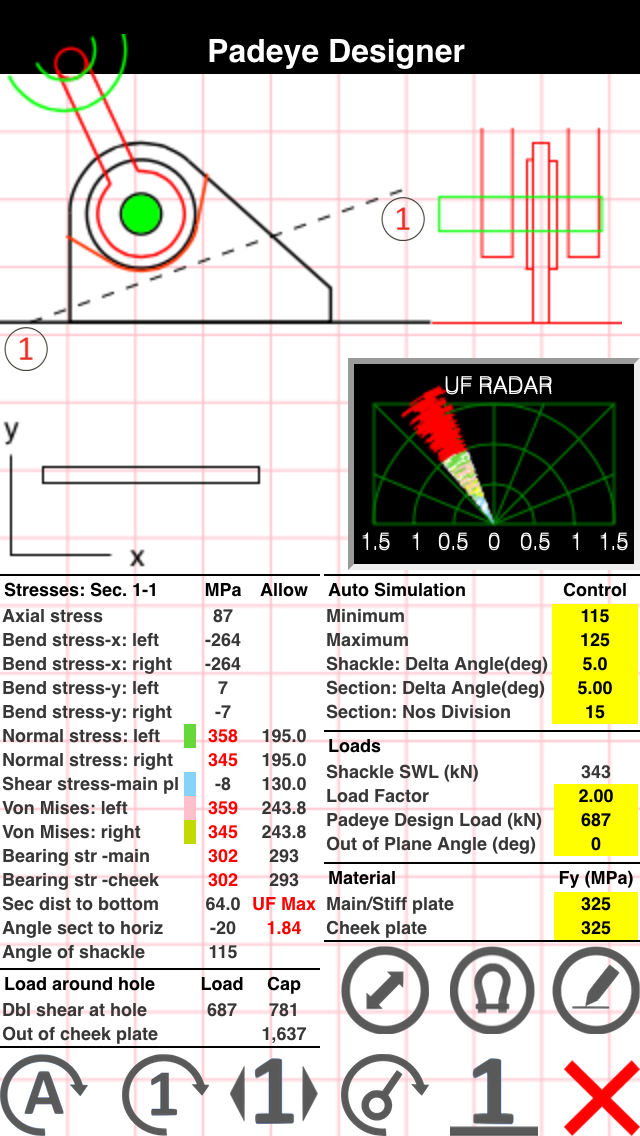

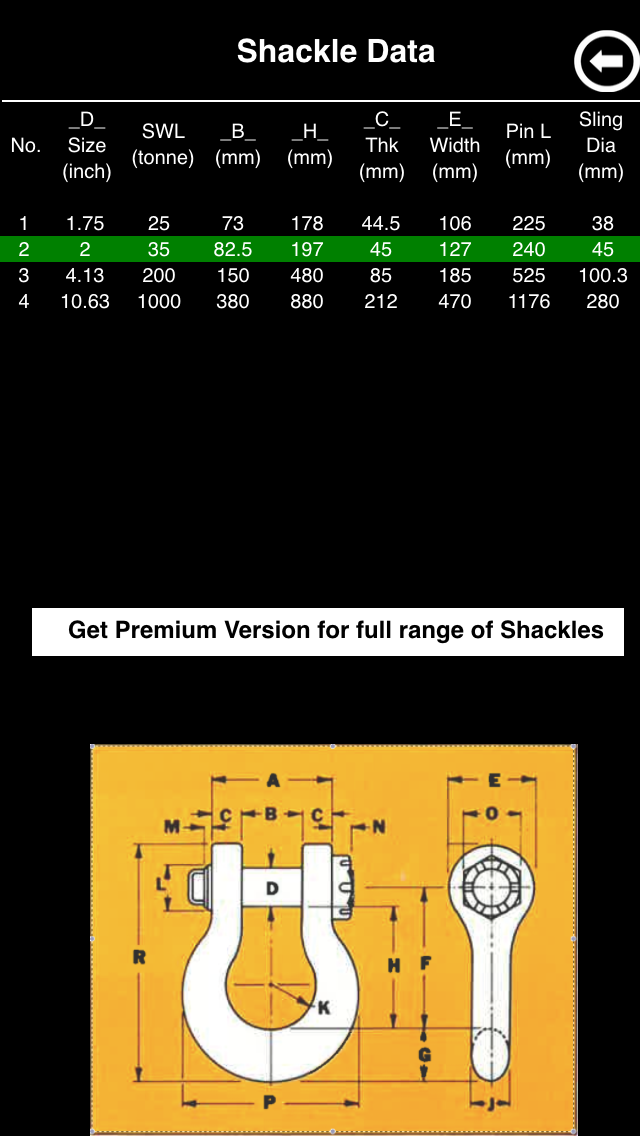

The Data Centre lists standard shackles available in the market with their SWL (Safe Working Load) and dimensions. The User chooses the one with the desired SWL and the App initiates an initial padeye sizing: the padeye sketch is shown in the Work Sheet. The User can modify the dimensions and design parameters in the Work Sheet seamlessly by touching the corresponding grid. Sliders are employed to check the stress state of sections through the padeye body and stiffeners if present. Any section of the padeye from base up to the padeye hole can be inspected for direct, shear and von Mises stresses. This is executed by an algorithm built into the App. The shackle working angle, i.e., the sling angle, can be rotated to match the design requirement using click and slide operation. An intuitive ‘UF RADAR’ screen is used to plot Utilization Ratios for all critical stresses at the section at any sling angle/shackle direction.

Up to four stiffeners can be included – these can be altered or removed as necessary. Separate yield stresses can be specified for the main and cheek plates. Bending and shear stress diagrams are shown for reference. The User can perform automatic checking by pressing button ‘A’: this directs the App to run a stress check using a set of pre-determined conditions.

All of the check features have been developed to ensure none are overlooked during the design process – which can happen with manual padeye design. A graphical approach is the main feature of the App so Users can easily visually inspect every detailed aspect of the design.

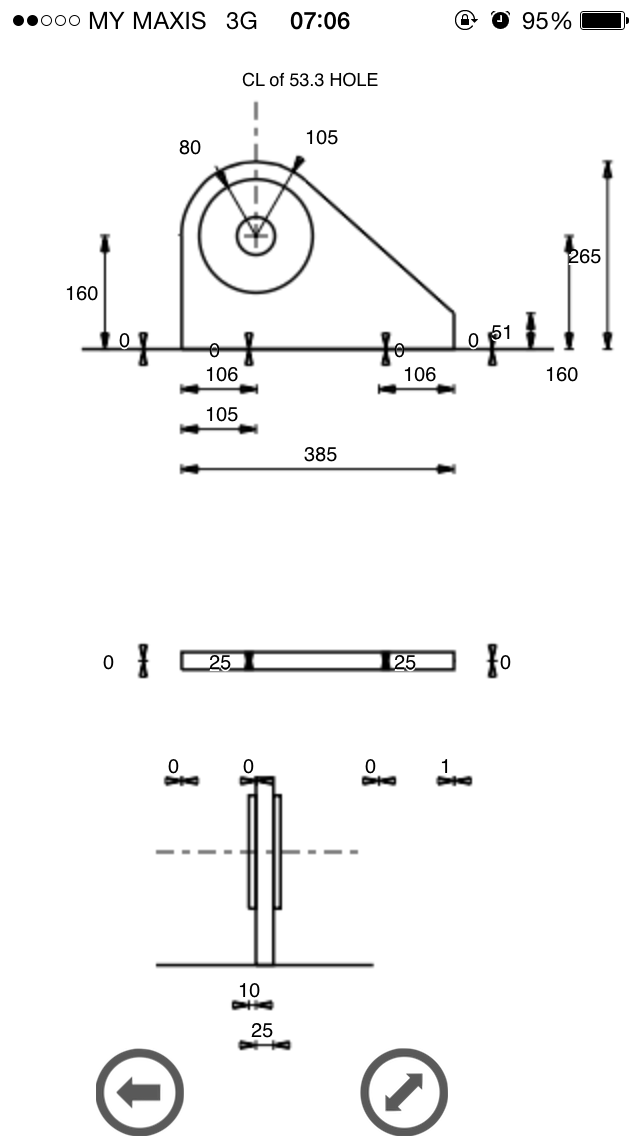

The User can also move to the Drafting Board to work on and produce a design drawing. The Board shows a formatted scaled drawing with all its dimensions and sections. The drawing includes title blocks, revision blocks and borders, which can be altered by the User. The scale of the drawing can be simply altered using a slider button. Every dimension on the drawing can be simply changed by the use of a slider or an input box. The stress state needs to be checked again via the Work Sheet.

An impressive feature of this App is the ability to trace an ‘actual padeye’ using an overlay screen. The User can take a photo of an actual padeye or of a design drawing to be used as reference. The User then traces the picture using all the features of the Drafting Board, i.e. zoom, move, rotate and dimension change. The User inputs the yield strengths and thicknesses of the main and cheek plates to enable execution of the stress checks via the Work Sheet. This feature is particularly useful for engineers to check or review a consultant’s design or to verify a padeye during fabrication.

Last, but not least, the App provides a Design Report that the User can print or send via email as a pdf or picture.

Uses – Quick check and review

- By Consultant when designing padeyes

- By Oil and Gas Operator when reviewing padeye design

- By Fabricator when reviewing actual fabricated padeyes

- By Offshore Installation Contractor (OIC) when reviewing design and fabricated padeyes

Benefits

- Cloud-based platform, use anywhere

- Ideal for onsite work

- Extremely efficient, instant analysis results.

For further information and to arrange for a demonstration contact us here